▍Product Features

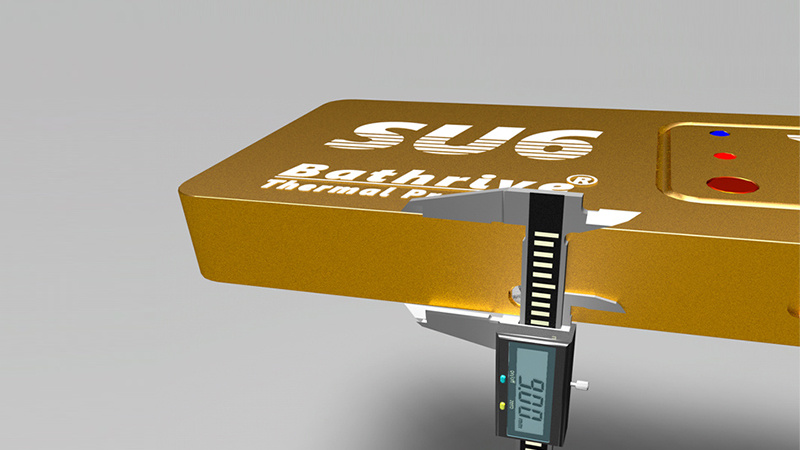

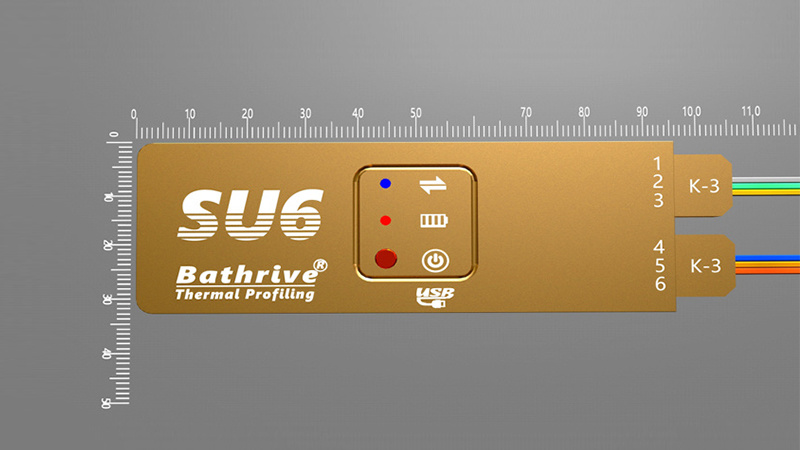

Bathrive® Su6 series instruments are especially suitable for scenes with limited temperature measurement space. They belong to the 6th generation of Bathrive® brand products. They are ultra-small in size and the thickness of the instrument host is only 9 mm, providing the possibility of accurate temperature measurement for scenes with extremely limited space.

▍Typical application fields of products

Electronic manufacturing, semiconductor, photovoltaic, spraying, brazing, new energy, metallurgy, glue curing (vertical furnace), food baking, etc.

semiconductor

electronics manufacturing

Photovoltaic

spraying

Brazing

new energy

metallurgy

food baking

▍Main function of the product

● Ultra-small size, built-in 32-bit high-speed processing chip with super computing power, making temperature measurement handy, and the design service life is more than 10 years

● High measurement accuracy +/-0.5°C, fast speed, the fastest 0.01 seconds/time, easily meet the challenges of various temperature measurement fields

● Data transmission mode, high-speed USB data transmission and charging are integrated, the battery is fully charged while transmitting data, no additional charging is required

● 3 trigger start modes and 4 trigger stop modes can be optimized and matched at will to realize intelligent start and stop without manual intervention

● Built-in 500MA high temperature resistant polymer rechargeable battery for power supply, can work continuously for 20~25 hours on a single charge (related to sampling frequency and number of channels)

● As many as 100 sets of curve overlapping analysis, support temperature, furnace, process and other data export, furnace temperature data import

● A maximum of 255 sets of temperature curve data can be saved

● Complete firmware information prompts, users can check the use record, status and hardware configuration information of the instrument at any time

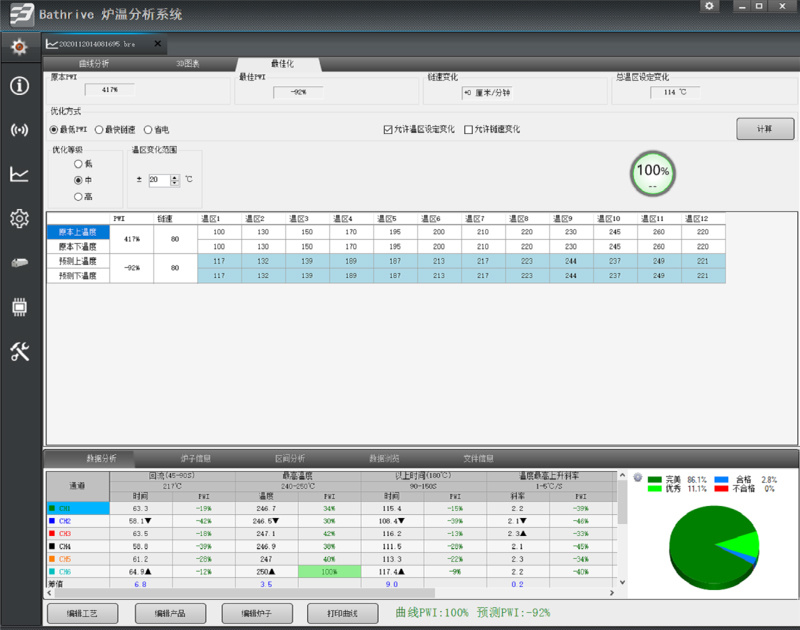

● Intelligent PWI index analysis, floating PWI, CPK indicators can visually display curve analysis results

● Manual and automatic curve optimization functions can effectively shorten the time for adjusting the oven. The data model of nearly one million temperature curves can provide users with the best recommended values for furnace temperature and chain speed. With the blessing of this function, novices can easily and quickly complete the oven temperature setting

● The instrument time can be set or calibrated to be synchronized with the computer

● Powerful curve editing functions, including curve clipping, curve alignment, curve moving and many other curve editing methods, make curve editing become arbitrary

● Curve tolerance zone display makes the reasonable variation range of the curve clear at a glance

▍Instrument technical specifications :

Instrument model: Bathrive_SU6

Number of channels: 6 K-type thermocouples (2 K-type components)

Instrument size: 95*34*9 (L*W*H) mm

Measurement accuracy: ±0.5°C

Temperature Resolution: 0.1°C

Sampling speed: 100 times/second~1 hour/time

Storage space: 256M

Number of storage groups: 255 groups

Battery capacity: 500MA explosion-proof button battery

Instrument start mode: temperature, time, button

Instrument stop mode: temperature, time, button, communication

Instrument working temperature: -40~105℃

Instrument temperature measurement range: -200~1370℃

Thermocouple Type: Type K

Communication port: USB

Software language: Simplified Chinese, Traditional Chinese, English

Software platform: WIN-XP, WIN7~10 (32 and 64 bit) Win-XP, 7, 10, 11 and above (32 or 64 bit system)

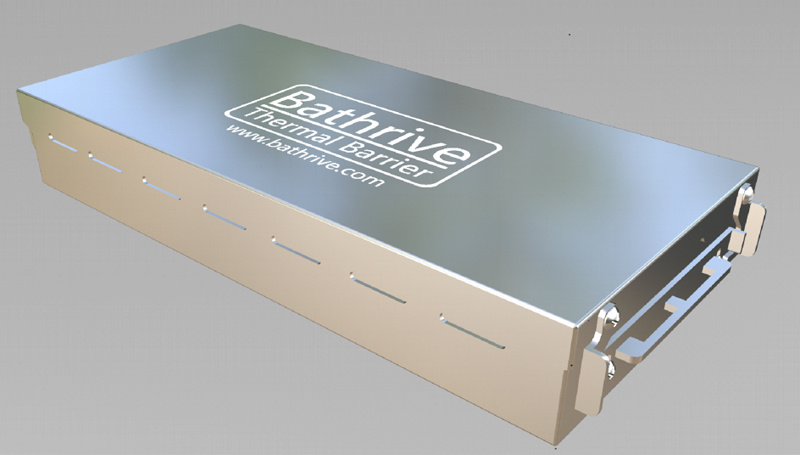

▍Heat insulation box

Adopting aviation-grade heat insulation technology, under the condition of certain temperature and space, the heat insulation time can be maximized, and heat insulation boxes of different specifications are equipped according to different usage scenarios

Phone

Phone